Munitions

We have worked with several DOD agencies on projects involving munitions research, reactive materials and obtained environmental clearances to perform large scale tests and disposal of energetic waste. Our work over the years focused on the development of models for prediction of munitions cook-off, impact induced ignition of reactive materials, and emissions from munition and energetic waste.

- Munitions Research and Testing

- Cookoff Analysis and Hazard Classification of Energetic Materials (Explosives, Propellants, etc.)

- Weapon Testing with ADORA

- Payload Technologies for Enhanced Target Defeat: Reactive Materials and Interhalogens

- Lethality Analysis

- OBOD

- Site permitting applications

- Environmental impact analysis

Slow Cook-off of PBXN-109 and PBXN-111

We developed an engineering model for the Slow Cook-Off (SCO) of explosive materials exposed to heat. We applied this model to a relatively insensitive munition composition, namely PBXN-109. We validated the model by comparing the predictions with small scale cookoff tests (Navy pipe bomb tests and Lawrence Livermore National Laboratory STEX) and Navy's full-scale tests (on a Heavy Wall Penetrator and a 500 lb GP Bomb). The casing temperature at cook-off and the time to cook-off predicted by our model agree well with the test data. Also, the strain data predicted by the model during the early stages of cook-off agree well with the measured strain gage data. The strain gage data are not reliable during later stages of cook-off as the gages become debonded from the vessel wall.

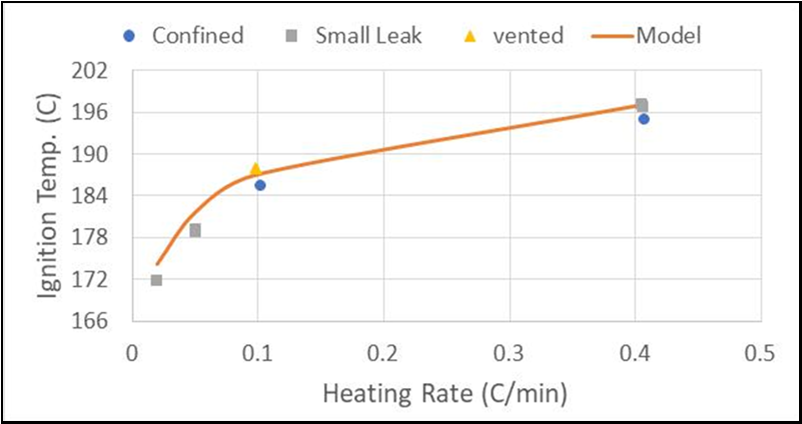

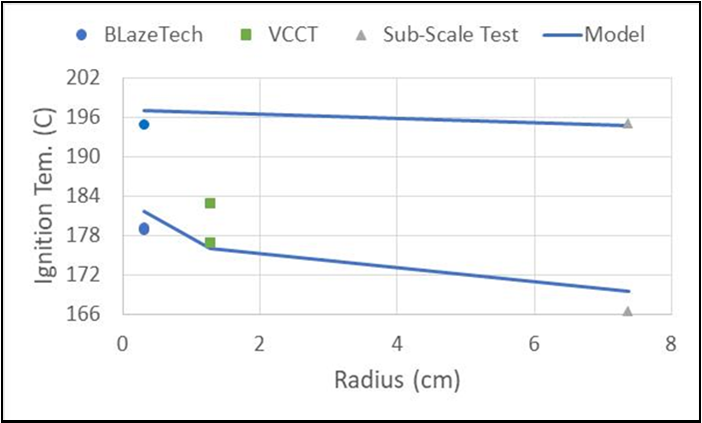

We also applied this methodology to PBXN-111. We first extracted kinetic data from small-scale experiments (~2g of explosive) of PBXN-111 conducted at Sandia National Laboratories. Isothermal tests of PBXN-111 pellets resulted in a thermal degradation model and controlled small-scale tests resulted in a burning rate model, which includes the dependence of the burning rate on pressure as well as extent of thermal degradation at initiation. Data was collected on both confined and vented PBXN-111 pellets.

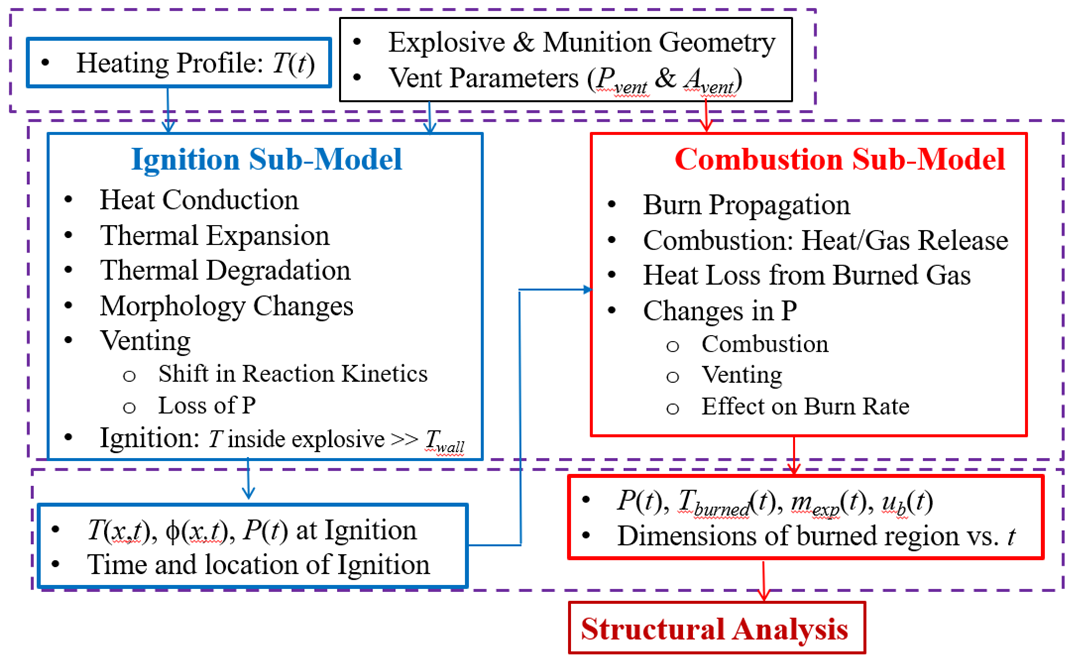

Fast-running engineering models were developed for ignition and combustion governed by the data from the thermal degradation and burn rate studies. Using the configuration (dimensions, ullage volume and casing wall thickness), heating protocol (heating rate, soak temperature and soak duration) and vent parameters (size and the pressure needed for activation) as inputs, the ignition model predicts the time to ignition and the conditions at ignition including temperature and porosity profiles, wall temperature and pressure. The model predictions agree well with ignition test data at different scales (covering ~3 orders of magnitude in mass) and heating rates (covering >1 order of magnitude) for PBXN-111, which serves as validation. Later, these models were coupled to CFD software that predicts the temperature as well as the location of ignition leading to munition cook-off.

Reactive Materials

We developed an engineering model to predict the high-speed impact induced ignition of Aluminum-Teflon RM-4 reactive fragments. We considered various hot spot mechanisms including void collapse, shear banding, frictional dissipation, and shock heating and their effect on reaction initiation. Shown in the image below is a sequence of events that occur during the high speed impact of RM-4 reactive fragment with a metal target plate.

Large Scale Enclosed Detonation Tests

For the US Army DAC, we evaluated the emission data from full-scale enclosed detonation tests at the Nevada Test Site X-tunnel involving M107 HE loaded 155 mm projectiles. In addition to examining the internal consistency of test measurements, we performed detailed mass and energy balance calculations and calculated the dynamics of cloud evolution and the composition accounting for both detonation and after-burn reactions. These calculations showed that the effect of containment by the tunnel walls on the cloud evolution is significant. Our predictions of major products and most minor products (such as VOCs and SVOCs) agreed well with the test data.

Munitions Disposal Through Open Burn and Open Detonation (OBOD)

For a DoD contractor, we performed OBOD calculations to determine the potential emissions from planned munition and energetic waste disposal operations. Our results were used in the preparation of environmental site permitting applications.

Validation of Open Burn and Open Detonation Model Using BangBox Data