Hydrogen

We performed several safety studies of the processing, handling, storage, and transportation of hydrogen in the chemical and transportation industries as well as its potential use in aviation. We have also conducted fire tests involving hydrogen and participated in national large-scale tests of the spill, dispersion, and ignition of cryogenic fuels.

Lockheed Proposed Hydrogen Fueled Aircraft

In an 1882 study for NASA, we compared the crash fire hazards of aircraft fueled by liquid hydrogen, liquid methane, and conventional jet fuel. A Lockheed aircraft design was used for the comparison. This was a 400 passenger, Mach 0.85, 5500 n. mile range, mission-equivalent to current airliners. The two cryogenic-fueled designs had insulated tanks located in the fuselage, front, and aft of the cabin while the conventional fuel aircraft had fuel in the wing tanks. For purposes of comparison, we considered four crash scenarios ranging from minor releases to a catastrophic crash. In each scenario, the potential fuel-release and crash fire consequences were compared for the three types of fuels. These include the resulting pool diameter, height, and duration as well as the heat flux from the fire and time-integrated thermal dose to the aircraft.

Rocket Launch Risks Modeling

At the onset of commercial space program promoted by President Reagan, the DOT needed a quantification of the risks associated with Expandable Launch Vehicles and their comparison to various industrial and transportation activities. We modeled the fire, explosion, and toxic dispersion for hazards associated with accidental releases of propellants during pre-launch and launch operations. We examined liquid and solid rocket motors, and hybrid engines in the Atlas-Centaur, Titan, Delta, and AMROC systems. The propellants included liquid hydrogen, liquid oxygen, hydrazine compounds, and nitrogen tetroxide, as well as solid propellants. The analysis covered handling, transportation, storage, and launch operations. The results of our source characterization and dispersion modeling showed significant improvement over existing models. To determine risk acceptability, the frequency and consequences of potential accidents were compared with historical data for hazardous materials associated with more common activities such as industrial and transportation accidents involving the same or similar chemicals.

Hydrogen Bubble in the Three Mile Island Nuclear Plant

In 1979, the loss of coolant produced a partial melt down of reactor number 2 in the Three Mile Island nuclear power plant near Middletown, Pa. The formation of a hydrogen bubble inside the reactor was suspected with concern on the potential for bubble detonation, failing the structural integrity of the reactor. The Electric Power Institute organized a national committee including Dr. Moussa to assess the potential hazard and what to do about it. A quantitative analysis was performed, and a test set-up was proposed to verify the results. The tests consisted of ¼ scale model of the reactor to duplicate the accident. It was built and operated by Factory Mutual.

TRansUranic Waste Drums

We examined the potential for flammability in TRansUranic (TRU) Waste Drums during their processing. When the potential exists for flammable conditions, we performed deflagration calculations to determine the pressure-time history. We also examined the conditions where the requirements for a detonation to occur were satisfied.

Deflagration of Hydrogen/air mixtures in TRansUranic Waste drums

Hydrogen Safety Assessments

Over the years we performed several studies on systems involving liquid hydrogen, particularly its release and the potential for fire and explosion. Examples of these systems included a future inertial measuring unit under development by Draper labs., a hydrogen-oxygen fuel cell built by Pratt and Whitney, and a hydrogen processing unit bult by a materials company.

Hydrogen Generated by Wetting of Magnesium

For the US Army, we evaluated the burning behavior of a one-of-a-kind mixture of magnesium particles and polymeric materials. Fire tests were carried out on individual 25-lb boxes of the mixture (up to six boxes at a time) and a suitable fire suppression method was determined. Also, the rate of hydrogen gas generation by accidental wetting of the mixture was measured under realistic conditions. The potential impact of such release in a warehouse was assessed using models. Finally, guidelines for the safe storage and handling of this material were developed and the manufacturer’s erroneous Material Safety Data Sheet was revised.

Tantalum Remelting Process

We examined the potential for hydrogen release during tantalum remelting process. The water cooled copper jacket used to cool the molten metal may get perforated causing the molten tantalum to come in contact with water. We examined the potential for the generation of flammable conditions due to the reaction between molten tantalum and water in this scenario.

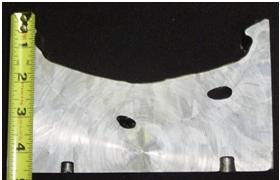

Hydrogen Release During Tantalum Remelting Process

Large-Scale Testing of Liquified Natural Gas

For the Coast Guard, we participated in design of the world's largest (10,000 gals) LNG spill fire test of its time. The tests were conducted in the California desert by the Navy. Both pool and vapor fires were produced by immediate and delayed ignition, respectively. We analyzed and interpreted the test data, measuring the burning rates and thermal radiation outputs, and identifying salient the features of these fires. These results guided model developments.

Risk Analysis

For several commercial clients, we carried out risk analyses of the processing, storage, and shipments of oil, natural gas, and various cryogenics and hazardous chemicals. First, we identified potential accident scenarios such as the accidental venting of gases or spills of liquids. Second, we performed HAZOP and Fault Tree Analysis to quantify the frequency of these scenarios. Third, we model their consequences such as the formation of jet fires, pool fire, fireball, BLEVE and vapor cloud fires. In each case, we calculated the fire size and the thermal radiation field around the fire to estimate the hazard zone. For the case of a potential explosion, we used a TNT equivalent analysis to estimate overpressure fields and translated them into hazard zones for building collapse, window breakage, etc. For toxic chemicals, we developed a unique model for reactive dispersion accounting for the coupling between chemical reactions and cloud behavior (ADORA). This model calculates toxic emission from explosions and fires including intermediary and final species. Fourth, we developed risk profiles to compare these industrial risks to those from natural causes and from voluntary activities.

Fault Tree Analysis to Quantify Accident Probability

For a major LNG import terminal, we performed Fault Tree Analysis. We quantified the probability of overfilling a Liquified Natural Gas tanker truck. We related this probability to the failure rates of equipment such as level gages, pressure sensors (etc.) and to operator errors. This analysis improved upon classical FTA by adding a pressure axis in the tree which enabled finer resolution of the sequence of events, the evolution of overfilling and probability of the accident.