FuelShieldTM

BlazeTech designs, develops, tests, and markets FuelShieldTM, a single system that protects aircraft fuel tanks against hydrodynamic ram, fire, and explosion. FuelShieldTM is based on our proprietary Ballistic Vulnerability Reduction System (BVRSTM) technology.

Comparison with Other Technologies

There are no proven technologies that mitigate hydrodynamic ram in aircraft fuel tanks. However, there are two concepts under development: fuel management and use of rigid foam backed structural panels (such as on CH-47 and UH-60 helicopters). The latter concept appears promising, but this technology is in a great state of flux as new foams are being tried and each foam has advantages and disadvantages. Generally, the protection is not enough and the volume requirement and the fuel displacement by the foam is not acceptable.

For protection against fire/explosion in the fuel tank ullage, there are three commercially available technologies:

- Ullage Inerting using nitrogen from cryogenic storage bottles (C-5) or from Onboard Inert Gas Generator Systems (OBIGGS on the C-17 and F-22). This adds a logistics penalty.

- Filling tank with flexible open cell polyurethane foam (e.g., on C-130, A-10, and F-15). Due to its limited life and stability, several changes of the foam are required during the life of the aircraft, increasing maintenance costs. These foams contribute to weight and volume penalties, and are prone to electrostatic problems.

- Halon fire suppression systems (F-16). Halon has been banned from production because of its adverse impact on the ozone layer. Alternate agents are under consideration.

The above protection systems suffer from severe cost, weight, and volume penalties.

Market Opportunity

A critical need of the DoD is to improve asset survivability under combat conditions. Such an improvement would minimize the damage to the assets, the time required for battle damage repairs and for readiness, the asset attrition rate, and the loss of life. Aircraft systems are particularly vulnerable because they are built from light materials that are easily damaged. Fuel tanks offer the greatest challenge because of their highly flammable content and large exposed areas.

Hydrodynamic ram, fire, and explosion lead to structural damage and fuel loss that result in mission failure or total aircraft loss (roughly $30 to $160 million per plane for the JSF and the F-22, respectively.) In the Vietnam War, approximately 40% of aircraft losses were attributed to fuel systems hits. In 1986, Live Fire Test law (LFT, 10 U.S.C. 2366) was passed which requires the determination of inherent strengths and weaknesses of weapons systems sufficiently early in the program to allow any design deficiencies to be corrected.

Improvement in fuel tank survivability is needed in all types of fixed- and rotary-wing military aircraft as well as certain ground vehicles. Such improvement is of particular interest to the Air Force, Navair, the Army AATD and their contractors including airframers and fuel tank system manufactures. Programs of particular interest are the Joint Services Battle Damage Tolerant Composite Wing Structure Program and the Composite Affordability Initiative. Systems of particular interest are the newer systems designs such as:

- Fighter planes: JSF and F-22

- Transport and Bombers: C-17

- Helicopters: V-22

- Reconnaissance planes: Global Hawk

FuelShieldTM can be installed on either new aircraft or retrofitted into the existing systems such as F/A-18E,F.

The military aircraft sector outlined above along with the large commercial aircraft sector form the primary market with the secondary market consisting of transportation and chemical industry in private sector.

Validation Tests

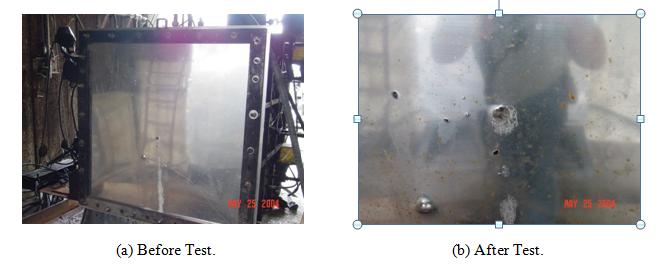

We performed large scale tests in a 40” x 40” x 40” cubical tank filled with about 100 gallons of jet fuel. The tank was equipped with 9 thermocouples, 11 pressure sensors (6 to measure the dynamic pressure at various locations in the ullage; and five to measure the quasistatic pressure. One of these five sensors measures the combustion pressure in the ullage) and a minicam for high speed recording of the explosion event. We performed baseline tests in which we shot the tank with a 110 gr inert fragment at about 5800 fps. Photographs of the exit panel before and after the fragment penetration test are shown below. Explosion in the tank completely destroyed the panel. A photograph of the test facility showing fire breaking out of the fuel tank into the surrounding space is also shown below.

Fire breaking out due to explosion in the fuel tank initiated by a high speed 110 grain inert fragment.

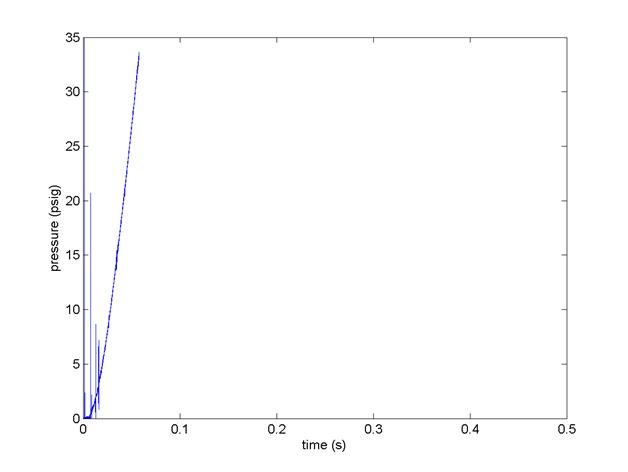

Pressure rise in the tank due to the explosion produced by the penetration of high speed 110 grain inert fragment into the tank in the baseline test.

Next we performed three repeat tests to assess the effectiveness of foam in mitigating the effects of high speed fragment penetration into the fuel tank. In each of these tests, we filled the same amount of jet fuel into the tank, but added an additive and stirred the fuel to produce fuel foam which filled the ullage. The photograph below shows the foam that fills the ullage of the fuel tank in one of the tests.

Photograph showing fuel foam in the ullage.

The photographs below show the exit panel before and after one of the tests (Test No. 4). As the high speed fragment punches through the front panel, it breaks up into smaller fragments that pepper the exit panel. The photograph of the panel after the test shows fuel foam leaking out through the holes. As the fuel foam mitigated the explosion, there was no fire during the test.

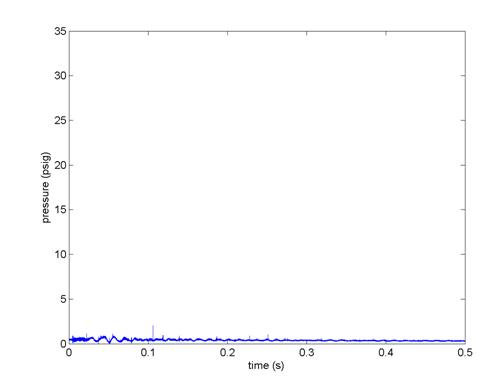

The figure below shows the pressure-time trace for one of the tests (Test 5). The figure clearly shows that the foam is highly effective in explosion suppression and so there is no net pressure rise in the tank during fragment penetration.

Pressure-time history in the tank during the high speed penetration of 110 grain inert fragment into the tank filled with fuel foam.